Wrapping is the tricky process of covering a sweet filling with a layer of chocolate. Fairly thin, liquid chocolate is pumped into the casing machine, where it is stirred and kept at a constant temperature.

Wrapping is the tricky process of covering a sweet filling with a layer of chocolate. Fairly thin, liquid chocolate is pumped into the casing machine, where it is stirred and kept at a constant temperature.The fillings should be warm enegizins when they go into the casing. But not the warmth that they do not lose their shape. The danger of a cold filling is that it will expand when it comes into contact with the cold filling, it will expand if it comes into contact with the warm covering.

Wrapping is a process that is used for bonbons, but also for the large-scale produced snack bars that are eaten all over the world.

Liquid chocolate is often poured into hollow molds to make figures (eg Sinterklaas, Easter figures, ...)

Liquid chocolate is often poured into hollow molds to make figures (eg Sinterklaas, Easter figures, ...)

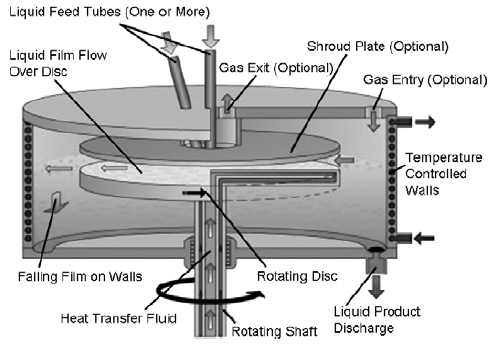

After conching, the chocolate goes into tempering kettles, where it is cooled while stirring, but remains liquid. It is very difficult to cool chocolate, because cocoa contains different types of fat and has a different melting and solidification point.

After conching, the chocolate goes into tempering kettles, where it is cooled while stirring, but remains liquid. It is very difficult to cool chocolate, because cocoa contains different types of fat and has a different melting and solidification point.